Vacuum Forming

The vacuum forming process involves heating a plastic sheet until it is soft and then draping it over a mould. A vacuum is applied sucking the sheet into the mould, setting it into a new shape. Vacuum forming can be used to produce a wide range of objects, from yoghurt pots to cat bowls, shower trays to vehicle interior panels.

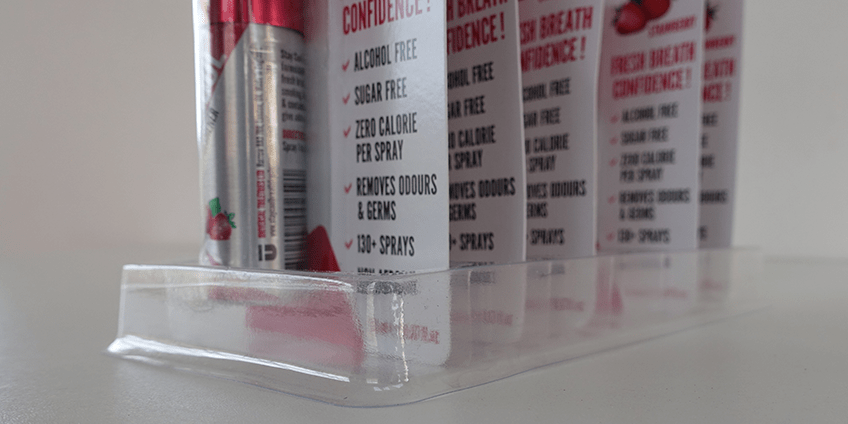

KPS Forming has extensive experience in setting up vacuum forming machines, using sophisticated pneumatic, hydraulic and heat controls to manufacture parts and packaging supplies. This also includes development of prototype tooling and specification of suitable thermoplastics for the intended use, with an eye for quality at a cost-effective price.